The Releated Products of Well Diamond Wire Saws

Well Diamond Wire Saws

Table of Contents

Well Diamond Wire Saws: Precision Cutting for Demanding Applications

In the realm of industrial cutting technologies, diamond wire saws have emerged as a powerful tool, revolutionizing the way hard materials are processed. Among these, well diamond wire saws stand out for their exceptional performance and versatility. This article delves into the world of well diamond wire saws, exploring their design, applications, benefits, and the factors to consider when choosing the right equipment for specific tasks.

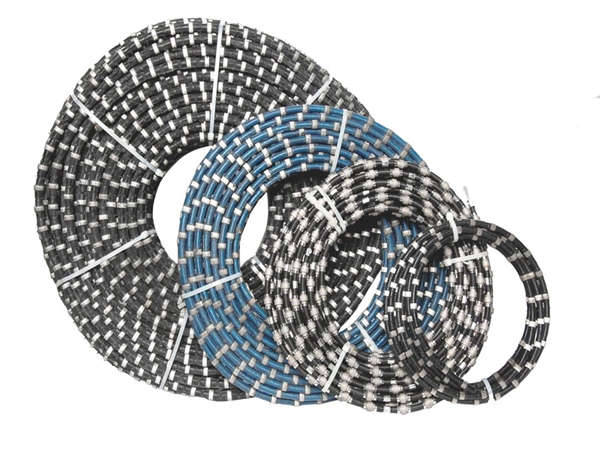

Well Diamond Wire Saws Design and Construction

The design of well diamond wire saws is centered around efficiency and precision. These saws consist of a thin, flexible wire embedded with synthetic diamonds, which serves as the cutting medium. The wire is typically made from steel or another durable material, ensuring it can withstand the rigors of continuous operation. Well diamond wire saws are engineered to cut through various materials, including concrete, stone, and reinforced metals, with minimal wear and tear. This robust construction not only enhances durability but also reduces maintenance costs over time.

Applications of Well Diamond Wire Saws

From construction sites to mining operations, the applications of well diamond wire saws are extensive. They are particularly useful in environments where precision and minimal vibration are critical. In the construction industry, these saws are employed for cutting concrete slabs, bridge decks, and other structural components. For mining and quarrying, they offer a safer alternative to traditional blasting methods, allowing for cleaner cuts and better control over the extraction process. The versatility of well diamond wire saws makes them indispensable across multiple sectors, driving innovation and improving productivity standards.

Benefits of Using Well Diamond Wire Saws

The adoption of well diamond wire saws brings numerous advantages to any project. One of the most significant benefits is the ability to achieve precise cuts with minimal material loss. This precision is crucial in applications requiring tight tolerances and smooth finishes. Additionally, well diamond wire saws produce less noise and dust compared to conventional cutting tools, making them ideal for use in confined spaces or sensitive areas. Their ability to work continuously without overheating also contributes to higher throughput rates and reduced downtime.

Selecting the Right Well Diamond Wire Saw

When choosing a well diamond wire saw, several factors must be considered to ensure optimal performance. Material type and hardness are primary considerations; different saws are designed for varying levels of hardness, so selecting one suited to your specific needs is essential. The size of the cut also plays a role; larger projects may require more powerful machines capable of handling increased loads efficiently. Lastly, the quality of the diamond segments on the wire is crucial for longevity and cutting effectiveness. Investing in high-quality well diamond wire saws from reputable manufacturers guarantees better results and longer service life.

Maintenance and Care of Well Diamond Wire Saws

Proper maintenance is key to maximizing the lifespan and performance of well diamond wire saws. Regular inspections should be conducted to check for signs of wear or damage to the wire and supporting hardware. Lubrication of moving parts helps prevent corrosion and ensures smooth operation. It’s also important to follow the manufacturer’s guidelines regarding storage and handling, especially during periods of non-use. By taking these precautions, users can extend the operational life of their well diamond wire saws, ensuring they remain a valuable asset for years to come.

Innovations in Well Diamond Wire Saw Technology

As technology advances, so too does the design and functionality of well diamond wire saws. Newer models incorporate features like improved diamond segment bonding techniques, enhanced tensioning systems, and more efficient motors. These advancements lead to better cutting performance, reduced energy consumption, and easier operation. Research and development efforts continue to push the boundaries of what these saws can achieve, opening up new possibilities for industries that rely heavily on precise material cutting.

In conclusion, well diamond wire saws represent a significant leap forward in cutting technology. Their combination of precision, versatility, and durability makes them an invaluable tool across multiple industries. By staying informed about the latest developments and best practices in using and maintaining these saws, professionals can harness their full potential, driving efficiency and innovation in their respective fields.

Request for Quotation

报错: 未找到这个表单