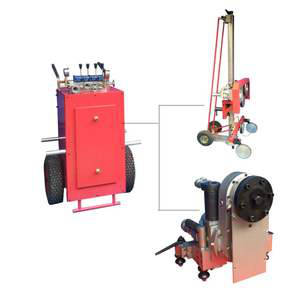

The Releated Products of Wet Circular Saw For Granite

Wet Circular Saw For Granite

Table of Contents

Choosing the Right Wet Circular Saw for Granite: A Comprehensive Guide

Granite, known for its beauty and durability, requires specialized tools for precise cutting. Among these tools, wet circular saws stand out as indispensable for achieving clean, accurate cuts without damaging the material. Whether you’re a professional contractor or a DIY enthusiast, investing in a quality wet circular saw for granite can significantly enhance your projects’ outcomes. This guide will explore key aspects to consider when selecting a wet circular saw for granite, ensuring you make an informed decision.

Understanding the Basics of a Wet Circular Saw for Granite

Before diving into specific models, it’s crucial to understand what makes a wet circular saw ideal for cutting granite. These saws use water to cool the blade and reduce dust during operation, which is essential when working with hard materials like granite. The cooling system helps maintain the integrity of both the blade and the material being cut, leading to smoother edges and longer tool life.

Blade Selection for Your Wet Circular Saw for Granite

The blade is arguably the most critical component of any wet circular saw used on granite. When choosing a blade, focus on diamond blades designed specifically for cutting granite. These blades have diamond segments that are bonded to the outer edge of the blade and are available in different grit sizes depending on the type of cut required. Coarse-grit blades are better suited for rough cuts, while finer grits provide more detailed work.

Water Cooling System in Wet Circular Saws for Granite

An efficient water cooling system is vital in maintaining optimal performance levels in wet circular saws for granite. This system helps in dissipating heat generated by friction between the blade and granite, preventing overheating that could damage the blade or the material. Look for saws with adjustable water flow settings, allowing you to control the amount of water applied based on the thickness of the granite and the speed of cutting.

Motor Power for Effective Wet Circular Saws for Granite

Power output is another critical factor when selecting a wet circular saw for granite. A powerful motor ensures that the blade can cut through granite smoothly and efficiently, reducing the risk of chipping or cracking. Motors typically range from 1.5 to 2.5 horsepower, with higher power being necessary for thicker pieces of granite or for continuous heavy-duty use.

Safety Features in Wet Circular Saws for Granite

Safety should never be compromised, especially when working with heavy machinery like wet circular saws for granite. Essential safety features include blade guards that cover the blade when not in use, anti-vibration handles to reduce operator fatigue, and dust collection systems to minimize airborne particles. Additionally, look for saws with emergency stop buttons for immediate shutdown in case of emergencies.

Maintenance Requirements of Wet Circular Saws for Granite

Regular maintenance is key to keeping your wet circular saw running smoothly and extending its lifespan. Key areas to focus on include cleaning the blade and water channels after each use to prevent clogging, checking the tension on the blade regularly, and lubricating moving parts to ensure smooth operation. Following the manufacturer’s guidelines for maintenance can help avoid costly repairs down the road.

By considering these factors—blade selection, water cooling efficiency, motor power, safety features, and maintenance—you’ll be well-equipped to choose the best wet circular saw for granite that meets your needs and budget. Remember, investing in a high-quality saw not only improves the outcome of your projects but also enhances safety and productivity in your workshop.

Request for Quotation

报错: 未找到这个表单