The Releated Products of Wet Table Tile Cutter

Wet Table Tile Cutter

The Precision of Wet Table Tile Cutters

Wet table tile cutters have become indispensable tools for professionals and DIY enthusiasts alike, offering unmatched precision and control when it comes to cutting tiles. Whether you’re working on a large-scale commercial project or simply renovating your bathroom, investing in a wet table tile cutter can make all the difference. These machines use a continuous stream of water to cool the blade while it cuts through tile, ensuring clean, straight lines and reducing dust.

Wet Table Tile Cutter: An Overview

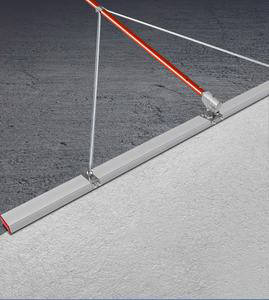

A wet table tile cutter is designed to provide a clean, precise cut by using a diamond blade that is constantly cooled with water. This process not only prolongs the life of the blade but also ensures that the tile is cut without chipping or cracking. The table design allows for easy movement of the tile against the blade, making it ideal for both straight and angled cuts. With its ergonomic setup, this tool reduces strain on the user’s back and arms compared to handheld tile cutters.

Key Features of a Wet Table Tile Cutter

When shopping for a wet table tile cutter, several key features should be considered to ensure you get the best tool for your needs. Look for models with adjustable fences and protractors that allow for accurate angle cuts. A powerful motor is essential for cutting through thicker materials like porcelain and granite. Additionally, a well-designed water reservoir and pump system keeps the workspace clean and safe.

How to Use a Wet Table Tile Cutter

Using a wet table tile cutter efficiently requires some basic knowledge and safety precautions. First, always wear protective gear such as goggles and gloves. Set up the cutter on a flat, stable surface away from electrical outlets due to the water involved. Measure and mark your tile accurately before placing it on the cutting bed. Adjust the guide according to your measurements, turn on the water supply, and slowly push the tile against the rotating blade for a smooth, controlled cut.

Benefits of Using a Wet Table Tile Cutter

The primary benefit of using a wet table tile cutter is the ability to achieve precise, professional-looking cuts. The continuous flow of water keeps the blade cool, preventing overheating and extending its lifespan. For intricate projects requiring multiple angles or curves, the adjustability of these machines shines through. Furthermore, the reduction in airborne dust makes them safer and more pleasant to use than dry-cutting methods.

Maintenance Tips for Your Wet Table Tile Cutter

Proper maintenance is crucial for keeping your wet table tile cutter in top condition. Regularly check and replace the cutting blade as needed to maintain sharpness and efficiency. Clean the machine thoroughly after each use, paying special attention to removing any tile residue from the water tray and moving parts. Store your cutter in a dry place to prevent rusting and corrosion. By following these simple steps, you can ensure that your investment lasts longer and performs better over time.

Choosing the Right Wet Table Tile Cutter for Your Project

Selecting the right wet table tile cutter depends largely on the scope of your project and your budget. Consider factors like the size of the tiles you’ll be working with, the frequency of use, and whether portability is important. Entry-level models are suitable for occasional home projects, while more robust, industrial-strength cutters are better suited for frequent commercial use. Always read reviews and compare specifications to find the model that best fits your requirements.

By understanding the capabilities and benefits of wet table tile cutters, you can tackle any tiling project with confidence, knowing that you have the right tool for the job.

Request for Quotation

报错: 未找到这个表单