The Releated Products of Wire Diamond Saw Stone Dressing

Wire Diamond Saw Stone Dressing

Table of Contents

Understanding Wire Diamond Saw Stone Dressing

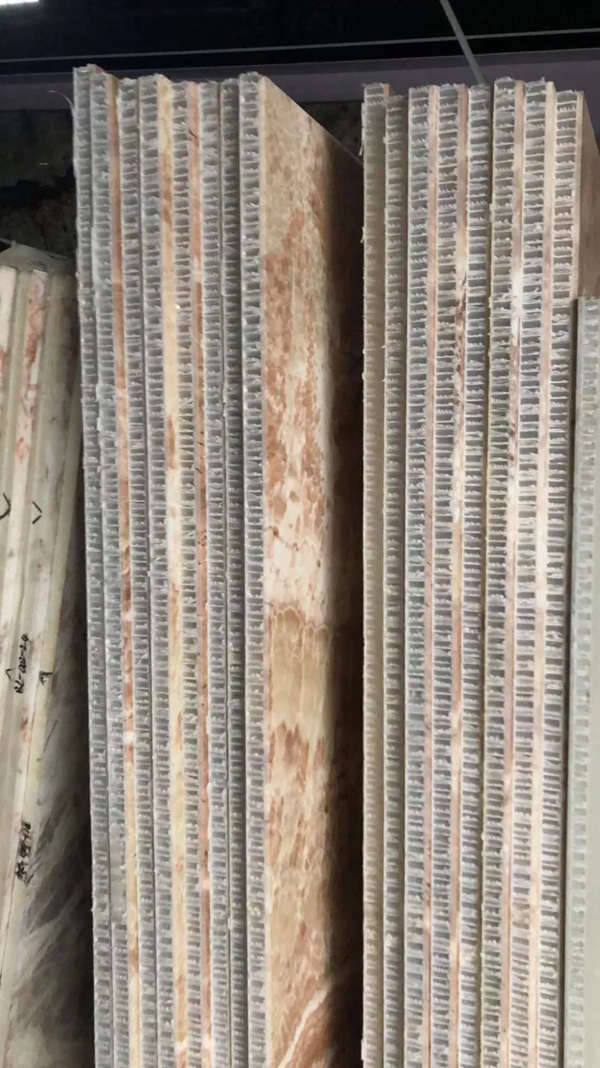

Wire diamond saw stone dressing is a specialized process used in the cutting and shaping of hard materials such as granite, marble, and concrete. This method has revolutionized the stone industry by providing a more efficient and precise way to work with these materials. By using diamond-impregnated wires, operators can achieve clean cuts with minimal waste, making it an environmentally friendly option compared to traditional methods.

Wire Diamond Saw Stone Dressing Techniques

When it comes to wire diamond saw stone dressing, several techniques are employed to ensure optimal results. One key aspect is the selection of the right wire for the job. Different stones require different types of wire based on their hardness and composition. For instance, softer stones might need a wire with a finer grit, while harder stones will benefit from a coarser one. Proper technique also involves maintaining the correct tension on the wire and ensuring consistent speed during the cutting process.

Benefits of Using Wire Diamond Saws for Stone Dressing

The use of wire diamond saws in stone dressing offers numerous advantages over traditional sawing methods. First, they produce smoother edges and cleaner cuts, reducing the need for further finishing work. Additionally, wire saws create less noise and dust, improving working conditions and safety. They are also versatile, capable of cutting through various materials with ease, and can handle complex shapes and intricate designs, making them indispensable in modern stonework.

Applications of Wire Diamond Saw Stone Dressing

Wire diamond saw stone dressing finds applications across a wide range of industries where precision cutting and shaping of stone are required. In construction, it’s used for creating architectural elements like countertops, flooring, and facades. In sculpture, artists rely on this technology to bring their visions to life, carving intricate details into solid blocks of stone. Even in the restoration of historical monuments, wire diamond saws play a crucial role in preserving heritage sites without damaging the delicate structures.

Maintenance and Care of Wire Diamond Saws for Stone Dressing

To ensure longevity and optimal performance, proper maintenance of wire diamond saws is essential. Regular cleaning of the wire and its supporting mechanisms helps prevent buildup of debris which can affect cutting efficiency. Lubrication of moving parts reduces wear and tear, extending the tool’s lifespan. It’s also important to periodically inspect the wire for signs of damage or wear, replacing it when necessary to maintain safety standards and cut quality.

Advancements in Wire Diamond Saw Technology for Stone Dressing

Recent advancements in wire diamond saw technology have made stone dressing even more efficient and effective. Newer models feature enhanced diamond segment designs that increase cutting speed and reduce power consumption. Some systems incorporate advanced cooling mechanisms to keep the wire at optimal temperatures, preventing overheating and prolonging its useful life. As research continues, we can expect further innovations that will continue to push the boundaries of what’s possible in stone processing.

By embracing the latest developments in wire diamond saw stone dressing, professionals can look forward to achieving higher levels of productivity and craftsmanship in their work. Whether you’re involved in construction, art, or historic preservation, these tools offer unparalleled precision and control, transforming how we interact with stone in our daily lives.

Request for Quotation

报错: 未找到这个表单